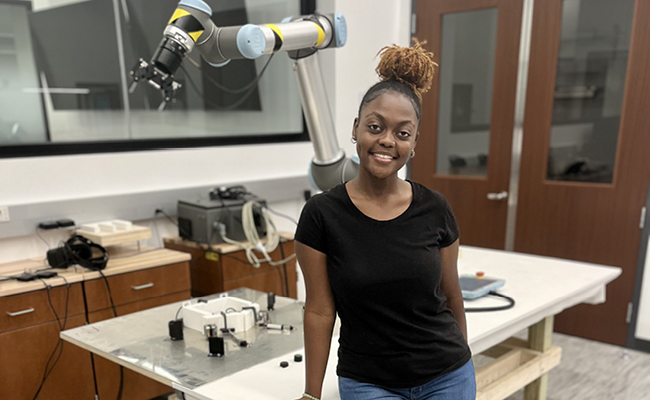

Janae Rapley

Janae Rapley, a student at Arabia Mountain High School in Lithonia, spent part of her summer getting a taste of what life is like in the University of Georgia College of Engineering. Janae was the first high school student hired to work in the Innovation Factory, a realistically equipped production facility in UGA’s new Interdisciplinary STEM Research Complex. The factory provides students an opportunity to explore real industry challenges while learning skills transferable to the workplace.

Janae wrote the following account of her experience in the Innovation Factory.

When I hear the word “engineering,” I think of innovation and creativity. When I was introduced to engineering during my freshman year of high school, I knew that I wanted to be a part of a revolutionary field that incorporates leadership, and problem solving into everyday living. With engineering on my mind, I was more than elated when I got the opportunity to meet Dr. Sonia Garcia at a UGA luncheon that I was invited to. Little did I know how much my encounter with Dr. Garcia would change my life.

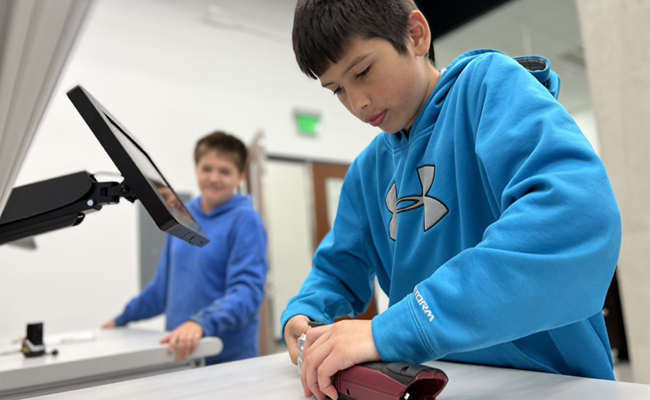

I was blessed with the opportunity to become the very first high school intern ever hired in the Innovation Factory! During my time at the innovation factory, I was introduced to a multitude of innovative technology, and procedures that will change the world of engineering and mechanics forever. While interning at the factory I was assigned to prepare a demonstration for children to display the capabilities of the innovation factory, and how the innovation factory ties into engineering. The demo focused on the capabilities of artificial intelligence, and how mechanical and civil engineering tie into everyday life. Another large part of the demonstration was to highlight the assembly line. Each student was able to pick a station and add parts to an oscillator. It was extremely rewarding watching children absorb and learn about engineering and assembly lines from my demonstration that I presented to them.

While at the factory I also worked on a large scale of things. I was able to program a karting game using the C# program! With gaming, I used Unity (which is coded with C#) to code a (go) karting game. Since coding with C# was a new thing for me, it was difficult in the beginning to remember all the steps, and functions of each button/tool. Along with C#, I also got the opportunity to become more aquatinted with python coding. Besides using python to code a small robot during my high school engineering class, I had little experience with python coding

Artificial Intelligence (AI) is a large part of the Innovation Factory, and I was also able to experiment with AI, as well as add it to my demonstration with the children. This was one of my favorite aspects of the lab. I was able to add my face into the facial recognition program with the help of one of my factory partners, Max.

As mentioned earlier I was introduced to an assembly line. But along with assembly, disassembling the creation comes next. A Disassembly line, as I have come to learn, is also equally important as an assembly line. At the disassembly line in the factory, each container has a specific weight that is recognized for the specific screw that is supposed to be placed in that container.

I am incredibly grateful that I got the opportunity to work with such an extraordinary team of engineers! I am very hopeful for the future of this program, and the future of our engineers!